.

RM-P60-RNH

Product Name : OpenMANIPULATOR-P

Model Name : RM-P60-RNH

User Programmable Open-Source Manipulator System

Modular Platform for Easy Maintenance and Customization

No External Control Box & High Weight-to-Payload Ratio

| OpenMANIPULATOR-P | 1 (Fully-assembled) |

|---|---|

| Hard Case | 1 |

| U2D2 | 1 |

| Spare Cables (4P, 2P) | 1 |

| Screw Sets (WB M3x8 etc) | 1 |

| 4P Expansion Hub | 1 |

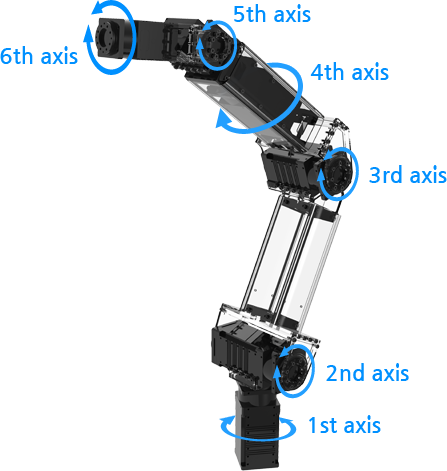

| DOF | 6 |

|---|---|

| Payload (kg) | 3 |

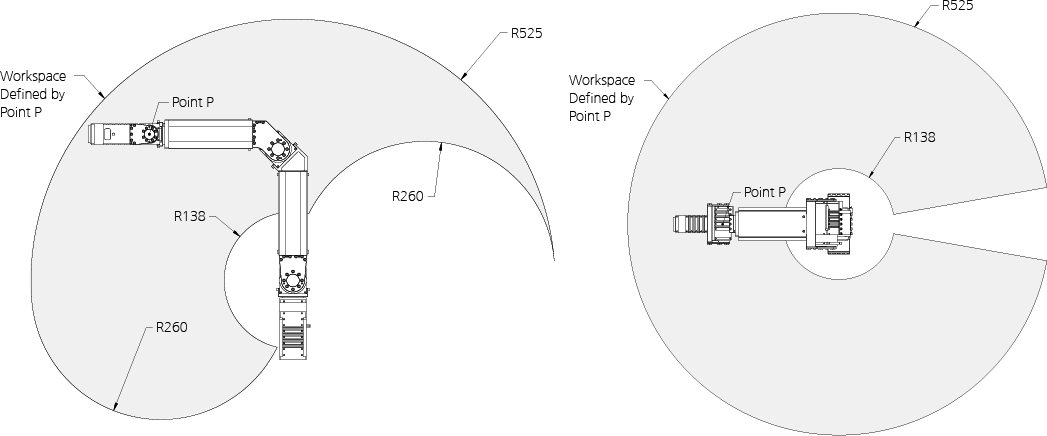

| Repeatability (mm) | ±0.05 |

| Speed (Each joint, deg/sec) | 180 |

| Weight (kg) | 5.5 |

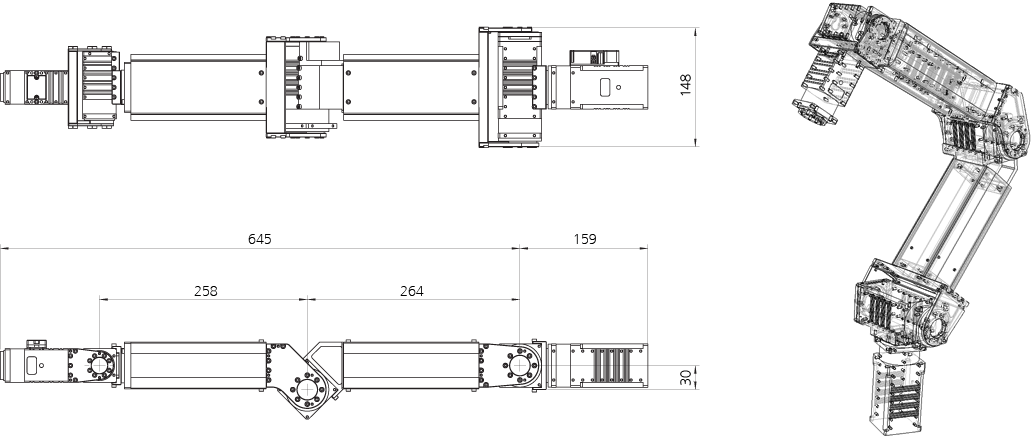

| Reach (mm) | 645 |

| Rated Voltage (VDC) | 24 |

| Communication | RS-485 (Multi Drop Bus) |

| Motor Output / Joint |

200W / 2ea 100W / 2ea 20W / 2ea |

| Software | ROS (Ubuntu Linux) |

|

Controller |

PC (Not Included) |

ROBOTIS Manipulator controller package based on integrated software

OpenMANIPULATOR-P Library (Kinematics,Trajectory and Dynamixel Controller).

GUI program package for setting and monitoring control parameters.

MoveIt! package for OpenMANIPULATOR-P

Simulation package based on Gazebo Simulator

Teleoperation examples of keyboard and Joystick

Research and Education

Kinematics and Dynamics Experiment

Research and Design a Dual Arm Robot

Build a Mobile Robot System

Industrial Operation

Inspection Equipment

Small-Scale Delivery System

Power supply and PC are not included.

Please purchase separately according to your usage environment.

.

| ID | 1 |

|---|---|

| Baud Rate | 57600 bps |

If you purchase RH-P12 (Robot Hand) and RM-P60-RNH(OpenMANIPULATOR P) together, they will be shipped out together in the OpenMANIPULATOR P`s case.

All-in-one Modular Design

DC Motor + Controller + Driver + Sensor + Cycloid Reduction Gear

Compact and Lightweight

Minimized module size with compact and lightweight cycloid reduction gear.

High weight-to-output ratio(0.05Nm/g)

High impact resistance ( over 400%)

High Precision and Low Backlash

Contactless (Magnetic) Absolute Encoder(by AMS) & Incremental Encoder for Precise Positioning

Low backlash (3~4arcmin)

Performance data provided tested by Korea Laboratory Accreditation Scheme(KOLAS)

Current-Based Torque Control

High speed current sensing algorithm and current feedback control

Triple-loop control for current, speed and position feedback.

User Friendly development environment

Provide C language based library

Various solution examples (C++, LabVIEW, C#, eclipse, JAVA, etc..)

- ○ e-Manual

- ○ Drawing

- ○ DYNAMIXEL SDK